It has been noted that ancient Roman roads are still intact after 2,000 years but nowadays, it seems our roads are in constant need of repair. Why is that? There are many reasons for short performance lives, but for now, we will focus on the Roman road cross section. After comparing the ancient methods with current practice, we see three factors that result in long performance life:

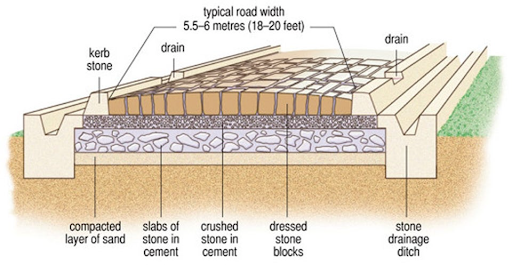

The roadway is designed for excellent drainage. Water flows from the crowned pavement to the gutters/ditch along the sides of the roadway. Where it is then carried away from the pavement structure via the ditches.

The roadway is built above the native elevations (that is the pavement is built with select materials, above the existing soil). Potentially poor soils and excessive grades are compensated by building a roadway over the identified issues. The built-up section also aids in drainage.

There are thick pavement layers. Each layer protects the layer below it. The native soil is shaped to minimize the effect of hills and valleys. Then a sand layer is placed to transmit subsurface water away from the pavement layers above. The next two layers are made of large and small rocks mixed with a cementitious material. A slurry of lime, sand and water was the common cement material. These layers could be a combined 18 to 24 inches thick. Finally, stones were cut, dressed (chipped by hand to shape and smooth the stone), and embedded to provide an even wearing surface. The resulting pavement cross section could be 36 to 46 inches thick. By comparison, today’s typical parking lot pavement cross section is about 18 inches – 3 to 4 inches of prepared soil; 8 to 12 inches of aggregate base and 2 to 4 inches of HMAC.

This is a great pavement structure and a remarkable construction feat. But the construction process was hugely labor intensive to prepare the soil, quarry and transport the rocks, and then hand place the rock. Even with modern techniques and equipment, this roadway would be difficult to construct. In its place, we use Portland cement concrete, colored and stamped to replicate a stone surface.

Figure from www.smithsonianmag.com/smart-news/why-ancient-roman-concrete-so-strong-180963946/

Blackstone Edge, on Rishworth Moor near Manchester, is remarkably well preserved with rain gullies and close-fitting cobbles still intact. www.historic-uk.com/HistoryUK/HistoryofEngland/Roman-Roads-in-England/