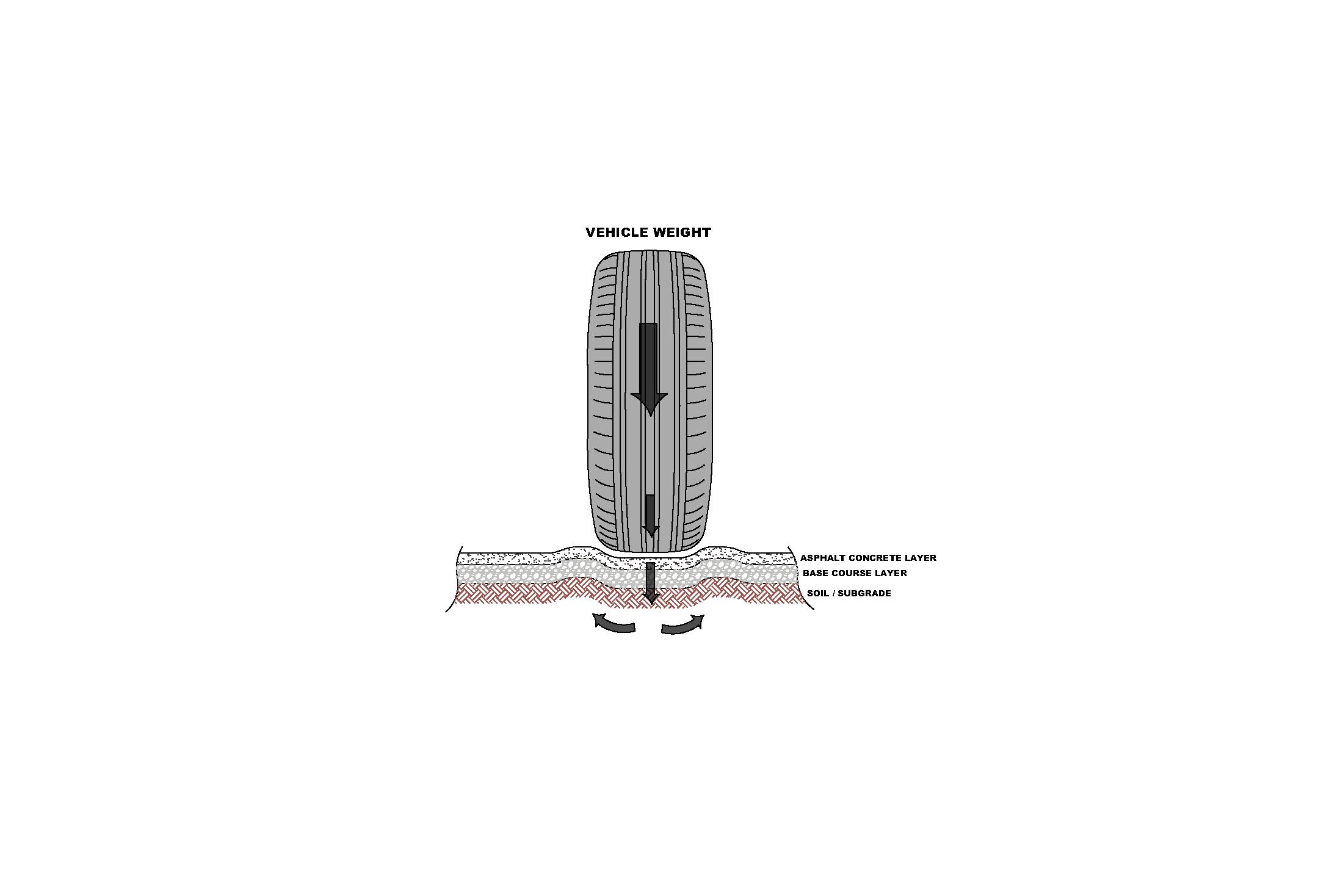

A typical combination of thin pavement structure (combined asphalt concrete and aggregate base layers) on top of a water-saturated (often found near landscaped islands), weak, fine-grained soil (silt or clay) allows, over a long-term, the vehicle weight to push down on the pavement structure. The actual term is material creep. The weight of the vehicle’s engine increases the depression depth at the front wheels. And for the lack of a better term, squishes the weak soil down and to the side, away from the weight or load. The Figure below diagrams this action.

We have tried repair methods and as you might expect, the more invasive and expensive the technique, the more effective. The cheapest repair is to fill the depressions with cold patch. But because the underlying weak soil condition is not addressed, the creep will continue. A better looking, but ineffectual repair is to surface mill a portion of the asphalt layer thickness and place a hot mix asphalt concrete overlay. We have removed a foot or two of pavement and soil in a strip at the front tire location. In the strip is an engineering fabric; added layers of stone; and an asphalt patch. This works well but removal depth is important, and costs increase with depth.

The most effective approach works in the entire parking area affected. The area is excavated 18 inches deep. If there are specific weak soils, they are removed. A plastic net-like sheet called a geogrid is laid on the soil. Then crushed aggregate or rock is placed in roughly 6-inch layers and compacted. Last, two layers of two inches of hot mix asphalt concrete are lain and compacted. What make this effective is the aggregate is pushed into and restrained by the geogrid openings in the geogrid and is restrained. Tension is created in the geogrid transferring the vehicle weight horizontally instead of vertically; thereby, protecting the weak soil.

Zimmer Consultants photographs